SCP Tech Brief: Moisture Testing of SCP-Treated Concrete

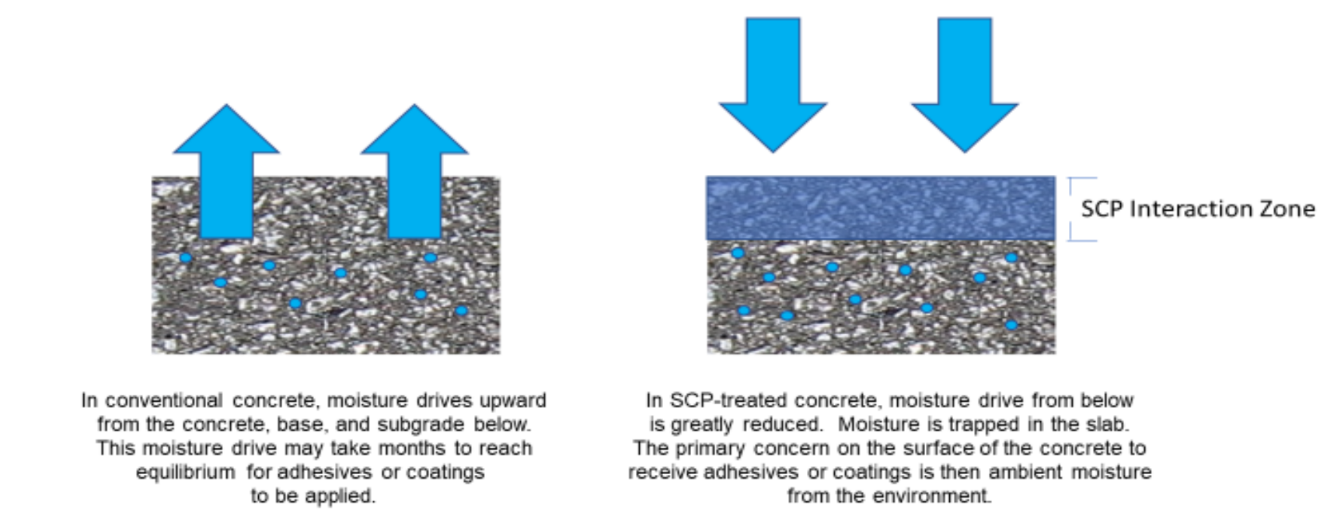

This letter is provided to address common questions of moisture testing Spray-Lock Concrete Protection (SCP) treated concrete. SCP technology is different than many moisture mitigation treatments because it penetrates the concrete matrix, blocking the concrete capillaries and pores instead of forming a coating/membrane on the surface. Some flooring and coating companies have had questions about testing SCP-treated substrates. Other systems for vapor control that are applied after concrete placement do not require testing because there are not relevant or applicable tests available. All treatments of coatings, reactive penetrants or patching and leveling systems preclude all standard tests for moisture vapor emissions.

SCP products work by penetrating the bleed water channels, capillaries, and voids left in the concrete as bleed water exits. Once in the concrete, SCP products react with available alkalis to primarily form Calcium Silicate Hydrate (C-S-H), the same reaction product provided by cement hydration that provides most of concrete’s desirable properties. This process allows for longer hydration of the concrete.

Moisture Vapor Emission Rate (MVER) testing is one of the most requested tests. The following are reasons of why the MVER Test (ASTM F1869-16a Standard Test Method for Measuring Moisture Vapor Emission Rate of Concrete Subfloor Using Anhydrous Calcium Chloride) should not be used for evaluating moisture evaporation rate of SCP-treated concrete subfloors.

ASTM F1869-16a states the following in the scope for the test standard:

1.Scope

1.2 This test shall not be used to evaluate the rate of moisture vapor emitted by gypsum concrete or floors containing lightweight aggregate.

1.3 This test shall not be used to evaluate moisture vapor emissions over coatings on concrete or through reactive penetrants or over patching or leveling compounds.

Based on the ASTM F1869 testing scope and how SCP products work within the concrete reacting with available alkalis, the test method should not be used to determine MVER for SCP treated concrete.

Another common test method requested is the Relative Humidity (RH) Test (ASTM F2710 Standard Test Method for Determining Relative Humidity in Concrete Floor Slabs Using In-Situ Probes). This test method determines that relative humidity in the concrete matrix by placement of a probe embedded into the concrete and readings taken once the probe has become acclimated to the surrounding concrete. SCP products trap moisture in the concrete to by blocking off the capillaries and void spaces. The reaction products formed fill the capillaries and voids and shutdown liquid water transmission. By trapping the moisture in the concrete, the relative humidity will typically remain high for an extended time period.

Other test methods of obtaining moisture readings can give misleading results as the previous test methods

SCP does not feel that these test methods provide useful information for determining the effects of SCP-treatment. SCP does not require testing for our warranty, nor does SCP warrant any test results. As with any remediation system for moisture, flooring or coating applications should proceed by the manufacturer’s directions without further testing.

If there is a concern of water or water vapor movement through the concrete matrix of SCP treated concrete, SCP recommends using ASTM D 4263-83 (reapproved 2018) Standard Test Method for Indicating Moisture in Concrete by the Plastic Sheet Method.

The areas would need to have any covering, coating, and adhesive removed, if the area is not exposed concrete. The standard states a minimum of 16 hours, SCP recommends at least 24 hours, but 72 hours is preferred. The sheeting should be placed in an area that is not on or near a location of an opening, crack, joint, or penetration in the concrete.

Moisture vapor transmission levels are reduced low enough for even the most moisture-sensitive flooring materials according to ASTM E96 test results. SCP products warranties can be found at www.concreteprotection.com

If you have any further questions or needs, please contact us at scptech@spraylock.com.