Spray-Lock Concrete Protection Technology with ASTM F710 Floor Prep

This tech brief is to address common questions of ASTM F710 Standard Practice for Preparing Concrete Floors to Receive Resilient Flooring and Spray-Lock Concrete Protection (SCP) treated concrete. SCP technology is different than most topically applied concrete treatments because it penetrates into the concrete matrix, blocking the concrete capillaries and pores instead of sealing the surface. Some flooring and coating companies have had questions about testing SCP-treated substrates, particularly ASTM F710-19e1 section 4. General Guidelines, 4.1 The section states “The surface of concrete floors to receive resilient flooring shall be dry, clean, smooth, and structurally sound. They shall be free of dust, solvent, paint, wax, oil, grease, residual adhesive, adhesive removers, film-forming curing compounds, silicate penetrating compounds, sealing, hardening, or parting compounds, alkaline salts, excessive carbonation or laitence, mold, mildew, and other foreign materials that might affect the rate of moisture dissipation from the concrete, the adhesion of resilient flooring to the concrete or cause a discoloration of the flooring from below. Question and concerns come in the fact that the standard lists “free of….silicate penetrating compounds” and “…other foreign materials that might affect the rate of moisture dissipation, the adhesion of resilient flooring to the concrete…..”.

Chemical Differences between SCP products and common topically applied silicates

SCP products are not silicate-based products. Common topically applied silicates are composed of Sodium (Na), Potassium (K), or Lithium (Li) chemically bonded to silica (Si). The common topically applied silicates already have a cation (sodium, potassium, etc.) bound to the silica to form a silicate. One of the results of this form of silica being used in concrete is that the resultant C-S-H formed after reaction with calcium hydroxides is a shorter chain morphology, leading to an unstable nature that is inferior to Portland cement/ water - formed C-S-H. Common topically applied silicates also produce potassium, sodium, or lithium hydroxides as byproducts. Conversely, colloidal silica has been shown to produce long chain C-S-H, sufficiently more stable than even the "natural" C-S-H formed during the hydration of the cement.

Spray-Lock Concrete Protection (SCP) products are classified as colloidal silica, consisting of a stable dispersion of nano-sized particles of amorphous silica. The colloidal particles consist of a charged nucleus which is surrounded by an extended diffuse ionic atmosphere. The colloidal state of subdivision consists of particles with a size sufficiently small (≤ 1 μm) not to be affected by gravitational forces but sufficiently large (≥ 1 nm) to show marked deviations from the properties of true solutions. Colloidal silica is one of the best sources of the pozzolanic reaction (conversion of calcium hydroxide to calcium silicate hydrate (C-S-H)) known to man. The colloidal silica reacts with calcium hydroxide in the pore space to form secondary C-S-H, reducing the size of capillary voids and pores, which leads to a denser and more homogenous structure, greatly improving the mechanical properties of the concrete.

SCP Products are not bond breakers

A bond breaker is a product that forms varying layers of separation between contact surfaces. SCP is a penetrating concrete treatment that does not change the surface of the concrete. An SCP application is not a coating and has no negative effect on bond integrity.

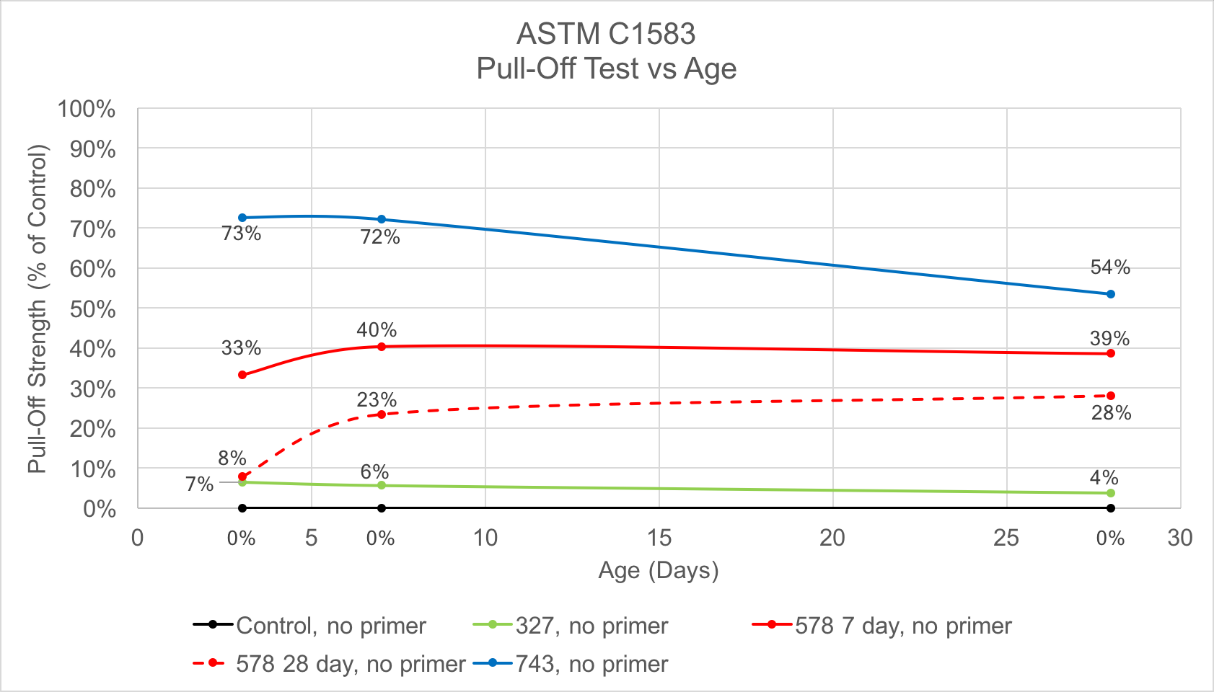

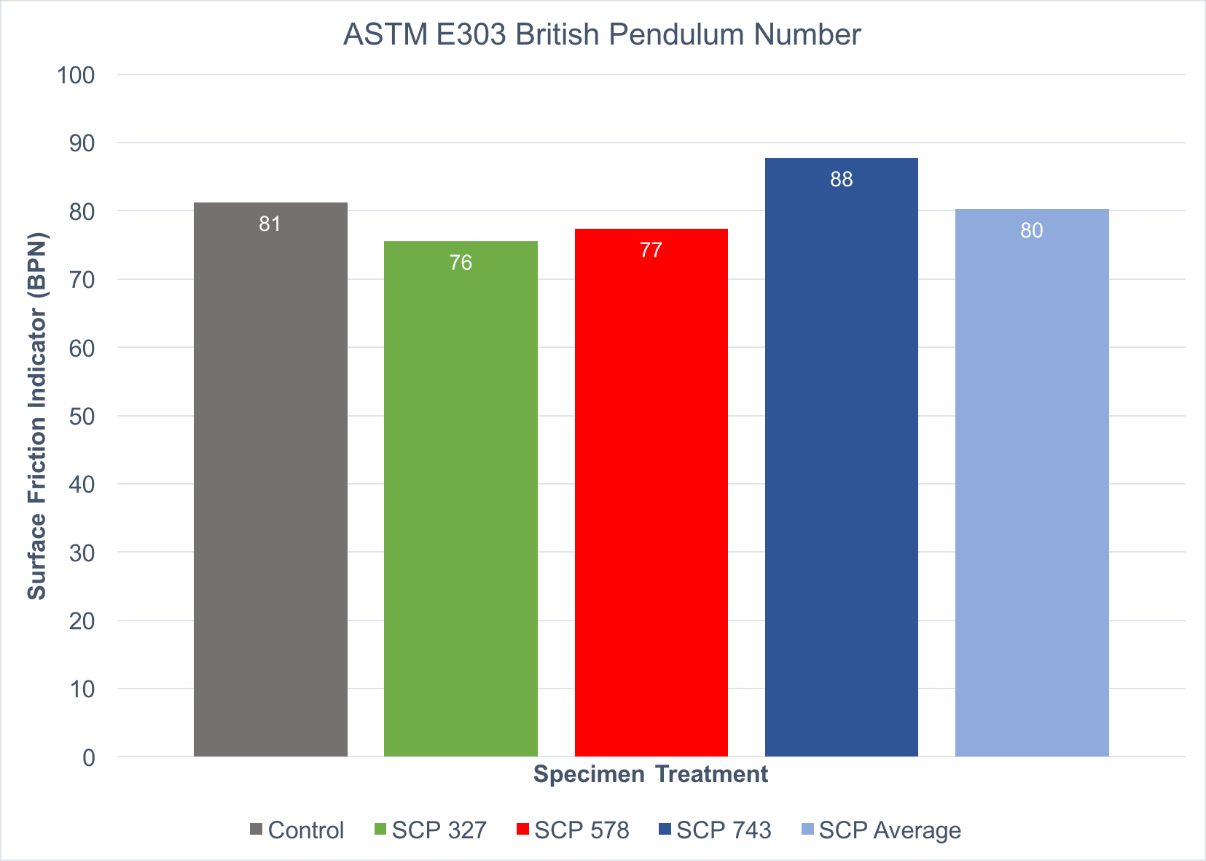

Testing of SCP’s application on concrete was performed to show that the product is not a bond breaker. Test methods included (1) ASTM C1583 Standard Test Method for Tensile Strength of Concrete Surfaces and the Bond Strength or Tensile Strength of Concrete Repair and Overlay Materials by Direct Tension (Pull-off Method) and (2) ASTM E303 Standard Test Method for Measuring Surface Frictional Properties Using the British Pendulum Tester.

In the ASTM C1583 test method, the concrete sample is cleaned of surface contaminants and loose or deteriorated concrete. The sample is then prepared to the typical surface conditions of the in-place concrete structure. The test material is applied and cured in accordance with the manufacturer’s specifications. After cure, a core drill is used to make a circular cut perpendicular to the surface. The test material is left intact on the concrete substrate, while a steel disk is attached to the top of the material using an epoxy adhesive. A tensile loading device is then attached to the steel disk to apply a tensile load to the test sample with force parallel to the vertical axis of the specimen. The load is applied until failure, and results are recorded.

In the ASTM E303 test method, the concrete surface is cleaned and freed of loose particles. The instrument is placed and leveled. The pendulum is lowered so that the edge of the slider just touches the concrete surface. Water is applied to thoroughly cover the test area. One swing is performed, and the reading is not recorded. Four more swings are made, and the surface is rewet before each swing. The results are recorded.

Testing shows that SCP Treatments increased the pull-off strength of concrete up to 73% compared to untreated concrete and had no statistical effect on surface friction. Since SCP Treatments become an integral part of the concrete matrix and are not surface coatings, additional treatments or removal prior to using a covering or coating are not required. Preparation to the level of concrete surface profile (CSP) required by the covering or coating manufacturer can be accomplished without interfering with SCP product performance. SCP products can be used in conjunction with all types of floor covering and adhesives without a negative impact on the flooring material or adhesion of flooring material.

SCP products work within the concrete matrix. Any joints, cracks, penetrations, or openings should be addressed separately. SCP recommends following ASTM F710-19, section 4. General Guidelines. Sub-sections 4.2 and 4.2.1 discusses surface cracks, grooves, depressions, control joints or other non-moving joints, and other irregularities. SCP also recommends discussing any material that will be used in these circumstances with the flooring manufacturer as well.

Conclusion

SCP products differ in form and function from conventional common topically applied silicates. The products are not in conflict with the F710 for floor preparation. The technology works within the concrete but leaves the mechanical key for the adhesive to bond to and not create a bond issue. SCP-treated concrete can be used with any flooring meant to be used with concrete.