P3 Industrial

P3 Industrial is formulated for use in a wide range of applications including warehouse floors, roofing, agricultural, parking structures and many more as P3 Industrial protects the concrete without forming a membrane, therefore it is not a bond-breaker. It is great for temporary roofing and as a replacement for traffic coatings. Ease of application with a high volume-low pressure sprayer will save the customer labor dollars. Concrete treated with P3 Industrial will better resist deterioration, providing superior results, allowing your concrete to last longer due to the reduction in penetration of contaminants such as salts, waste, efflorescence and carbonation.

Tested in general accordance with ASTM C 666, C 1556, E 96; EN 12390-8

P3 Protect

P3 Protect is the premium standard for exterior concrete protection on the market today. P3 Protect technology protects the concrete from the inside-out against intrusion from chlorides and other salts, animal waste, surface contamination, mold/mildew and carbonation exposures. P3 Protect is easily applied with a high volume-low pressure sprayer, making it ideal for the customer looking for a superior concrete cure (equal to or better than a 28-day moist cure), thus eliminating the need for an additional curing membrane. P3 Protect provides superior protection for driveways, sidewalks, concrete trails, salt sheds and many other exterior applications

Tested in general accordance with ASTM C 666, C 1556

P3 Marine

P3 Marine technology provides superior protection for concrete in coastal areas exposed to saltwater spray, splash zones, tidal zones, or water carrying other contaminants. P3 Marine was formulated to protect the concrete from the inside-out, thus greatly reducing the impact of chloride and other salts, as well as other contaminants in a marine environment. By reducing salts and other contaminants from penetrating the concrete, you realize a longer lasting and more durable concrete. The results provided from P3 Marine, coupled with the ease of application, makes this the ideal concrete protection solution in any marine environment.

Tested in general accordance with ASTM C 1556, C 1803; NT 492; EN 12390-8

Permeability Reducing Additive

Spray-Lock Concrete Protection (SCP) technology was developed in the late 1970s to solve concrete permeability issues in some of the harshest conditions possible. Decades later, the term Permeability Reducing Admixture (PRA) entered ACI 212 to address the long-standing benefits obtained from preventing moisture movement in concrete, something SCP has known to be true for over 40 years.

Amorfa reduces permeability while enhancing the overall characteristics of the treated concrete; working inside the concrete matrix to disconnect the capillary structure and generate resistance to fluid movement either into or out of the concrete. The level of resistance to fluid penetration ranges from a general reduction or to the levels required by hydrostatic pressures and aggressive exposures (PRA per ACI 212).

Tested in general accordance with NT 492; EN 12390-8

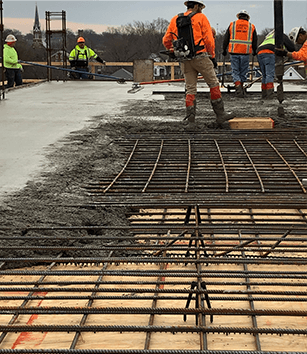

Concrete Durability

Concrete’s durability is its inherent ability to withstand deterioration. Many factors go into the durability of concrete. Some influences that affect concrete durability are water to cementitious ratio, aggregate packing, reinforcement and type, curing methods, type of environment the concrete will be placed, finishing practices. Concrete is a versatile construction component but due to its porous nature and bleedwater channel formation, contaminants can be introduced into the concrete. All concrete, especially reinforced concrete is susceptible to contaminant ingress. The corrosion potential of reinforcing steel is directly related to the chloride movement into the concrete, disrupting the protective layer around the reinforcement and leading to rusting. SCP products can help reduce the corrosion potential of concrete by reducing the pathways of water and contaminate ingress. The P3 product line consists of spray-applied products that use colloidal silica technology to provide a permanent increase in the durability and lifespan of Portland cement concrete.